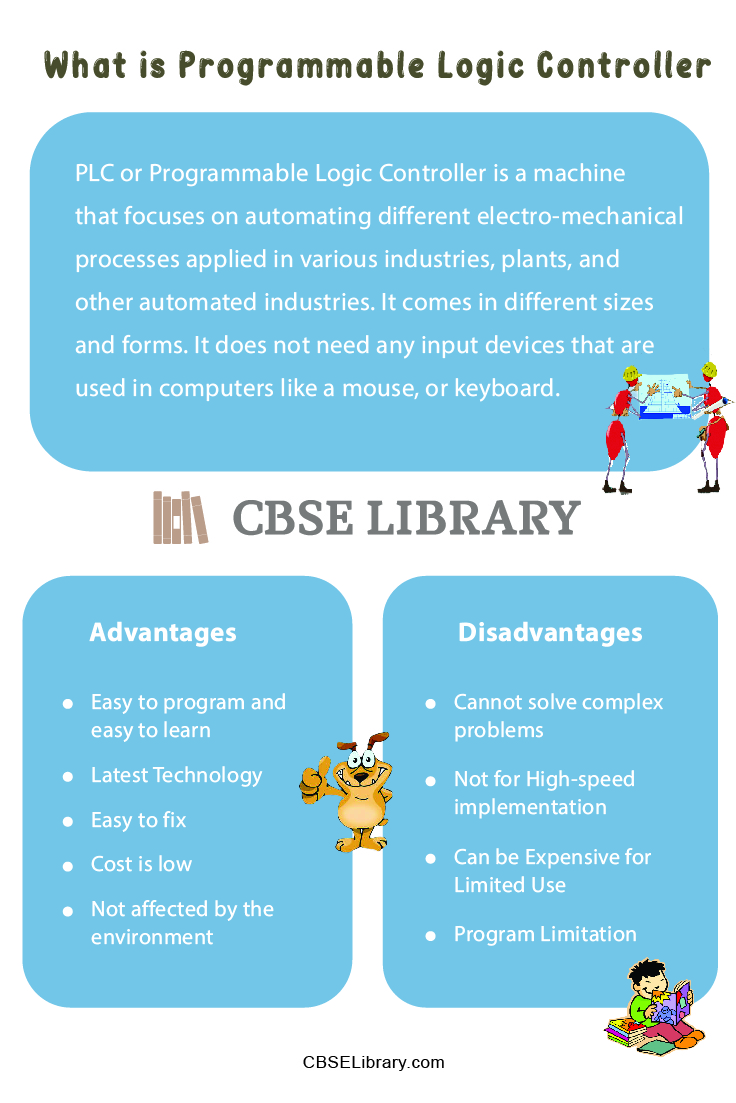

PLC Advantages and Disadvantages: PLC or Programmable Logic Controller is a machine that focuses on automating different electro-mechanical processes applied in various industries, plants, and other automated industries. It comes in different sizes and forms. It does not need any input devices that are used in computers like a mouse, or keyboard. They are widely used in industries because they are easy to be programmed and give good output also it is fast. They can be easily programmed for smaller tasks to major applications. Here the coding is transferred to PLC by cable and then processed in CPU, then it is applied to various machines that are automated by this application program.

Students can also find more Advantages and Disadvantages articles on events, persons, sports, technology, and many more.

What is PLC? How does it Work? PLC Advantages and Disadvantages 2022

Programmable Logic Controllers or PLCs are widely used in industries, plants, and automated manufacturings. They are electro-mechanical processes that are used very commonly in industries to control specific processes or whole processing units of the industries. They can be easily programmed for smaller tasks to major applications. It is used in mostly all types of manufacturing industries like automotive, food, printing, etc. It works when it gets the input through sensors or another input mode, then it processes and gives output according to the programmed format. It works on a fully automatic system from start to finish. One of the best examples for the PLC is the traffic light signal, automated doors, elevators, etc which are fully automated and works with the logic of PLC. Let us see below how a PLC works.

How does PLC work?

PLC works with the three main components which are

- The Power supply and the rack: The rack holds all the modules together and the power supply DC power supply to the modules that are in the rack.

- The central processing unit (CPU): Different types of CPU are required by the manufacturers based on the system. It has different operating modes and consists of microprocessors, a control unit, and a logical unit, and also communicates with the other module. Then it runs continuously with the same programmed system and also stores.

- I/O sections: Here Input devices are like pressure transducers or flow meters that are analog or digital and Output sections are also digital and analog-like led bulbs, small motors which get switched on or off as a programmed output.

A PLC software is programmed in Ladder Logic programming language because it is easy to implement and PLC software is developed first on a computer.

- Advantages of PLC

- Disadvantages of PLC

- Comparison Table for PLC Advantages and Disadvantages

- FAQs on PLC Pros and Cons

Advantages of PLC

PLC also known as a programmable logic controller is the system-generated software that is used in many industries for automated manufacturing with an electro-mechanical process. It is adaptable to almost all applications. Let us discuss the various advantage of PLC

- Easy to program and easy to learn: PLC software is programmed in Ladder Logic or another simple programming language because it is easy to implement and PLC software is developed first on a computer built in its memory. Also, the input and output terminals are attached to it so that any improvement or correction can be done easily.

- Latest Technology: PLC is the latest technology that is used widely in industrial and manufacturing processes. The old technology was dependent on relays and contactors but PLC not only is the best replacement for this but also can manage to do many other tasks.

- Quick Response Capability: PLC work in real-time means we can get output instantly with the event taking place in the field. It is designed for high-speed performance. It is fast and can easily give respond to the process very quickly.

- Cost is low: Though it is not dependent on relay control logic so it does not require any huge expense and installing PLC is much cheaper than using many relay control logic. Always it is a better option than the old model with the benefit of easy maintenance.

- Easy to fix: PLC runs in real-time and troubleshooting any problem is very instant with it. We can correct the problem in real-time and check. It is easy to maintain.

- Not affected by the environment: The industrial environment does not affect the PLC. it does not get damaged or get defects due to industrial noise pollution or other obstacles.

Disadvantages of PLC

Here are some disadvantages of PLC

- Cannot solve complex problems: Though PLC is compact with advanced technology and save any math problems solving complex math problem can be difficult for PLC as an industrial computer is more efficient to do this.

- Not for High-speed implementation: Some of the high-speed implementations cannot be achieved by a PLC. as we need for positioning and robotics which need a very high-speed implementation that is not suitable for PLC.

- Can be Expensive for Limited Use: We cannot use PLC in every application where there it is not needed. Because the unnecessary cost of programming can be added. Instead, the small applications can be run by relay.

- Program Limitation: Here we can run one program at one time which is time-consuming.

These were the advantages and disadvantages of PLC that explain its use and limitation of PLC.

Comparison Table for PLC Advantages and Disadvantages

| PLC Advantages | PLC Disadvantages |

| Easy to understand and easy to learn | Can run one program at one time |

| It is an advanced technology with advanced features | Gets expensive for limited use |

| Gives a quick response and capability to do tasks instantly | Cannot solve complex maths problems |

| Cheaper and takes low maintenance | For the high-speed implementation it does not work |

| Easy to fix problems | Can damage the system during power restoration |

| Do not get affected by the industrial environment | PLC hardware should be of the same manufacturer |

FAQs on PLC Pros and Cons

Question 1.

What is PLC? And what are its uses?

Answer:

PLC or Programmable Logic Controller is a machine that focuses on automating different electro-mechanical processes applied in various industries, plants, and other automated industries. It comes in different sizes and forms. PLCs are widely used in industries because they are easy to be programmed and give good output also it is fast. It works on a fully automatic system from start to finish. One of the best examples for the PLC is the traffic light signal, automated doors, elevators, etc which are fully automated and works with the logic of PLC.

PLC is used in the following applications

- Washing machines

- Burner management systems

- Traffic light signal

- All the manufacturing industries

- Escalator operation, etc

Question 2.

How does PLC work?

Answer:

PLC works with the three main components that are

Power supply and rack: The rack holds all the modules together and the power supply DC power supply to the modules that are in the rack.

The central processing unit(CPU): Different types of CPU are required by the manufacturers based on the system. It has different operating modes and consists of microprocessors, a control unit, and a logical unit, and also communicates with the other module. Then it runs continuously with the same programmed system and also stores.

I/O sections: Here Input devices are like pressure transducers or flow meters that are analog or digital and Output sections are also digital and analog-like led bulbs, small motors which get switched on or off as a programmed output.