Advantages And Disadvantages Of Hydraulic Systems: Hydraulic systems are complicated fluid-based systems for transferring energy or power into useful work. This system was started at the beginning of the industrial revolution when a British mechanic Joseph Bramah followed the principle of Pascal’s law in the construction of the first hydraulic press. He also patented his discovery hydraulic press and named it the Bramah press. It has the ability to transmit power instantaneously because hydraulic fluid is incompressible and it also transfers the energy from one point to another.

Students can also find more Advantages and Disadvantages articles on events, persons, sports, technology, and many more.

What is a Hydraulic System? What are the advantages and disadvantages of a Hydraulic System?

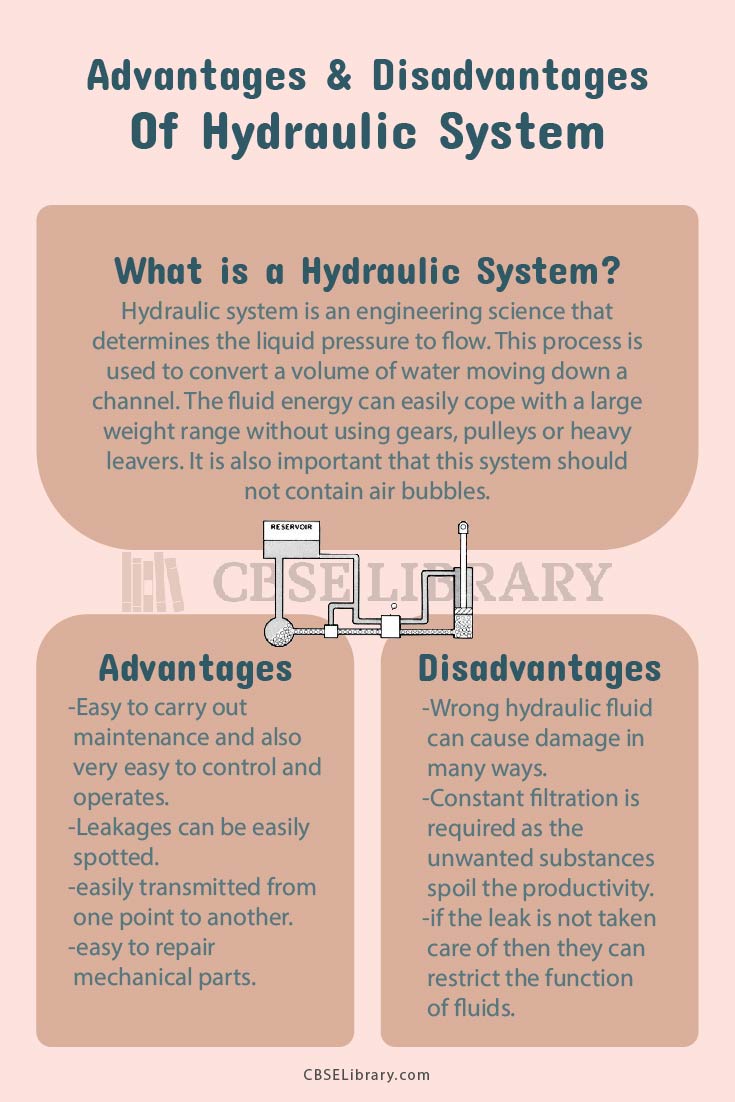

Hydraulic system is an engineering science that determines the liquid pressure to flow. This process is used to convert a volume of water moving down a channel. The fluid energy can easily cope with a large weight range without using gears, pulleys or heavy leavers. It is also important that this system should not contain air bubbles. If there is an air bubble in the system, the force applied to the first piston will compress the air in the bubble rather than moving the second piston. The fluid remains some sort of oil in the base and the force is almost multiplied in the process. One should be very careful and familiar with any equipment while using it to create hydraulic energy, workers should get proper training as well as protection for conducting all the procedures.

- Advantages of Hydraulic System

- Disadvantages of Hydraulic System

- Comparison Table for Advantages and Disadvantages of Hydraulic System

- FAQ’s on Advantages And Disadvantages Of Hydraulic System

Components of Hydraulic System

The major components of a hydraulic system are as follows:

- Reservoir: The purpose or use of a hydraulic reservoir is to hold a volume of fluid, transfer heat, allow solid particles to settle and release the air and moisture from the fluid.

- Pump: All hydraulic pumps work on the same principle as they displace a volume of the fluid against a resistant load or pressure. Pump transmits mechanical energy into hydraulic energy and there are several types of hydraulic pumps which includes gear, vane and piston and all have different subtypes too.

- Valves: These valves are used in a system to start and direct fluid flow. Valves are made up of poppets and can be used in several means of pneumatic, manual, hydraulic and mechanical ways.

- Actuators: Actuators are the end result of Pascal’s law. In this hydraulic energy is converted back to mechanical energy and it can be done through the use of a hydraulic cylinder and energy can be converted into linear motion to work. Hydraulic pumps, cylinders and motors have several subtypes.

Types of Hydraulic Systems

Open-loop hydraulic system: In the open-loop hydraulic system, the mechanism is idle and the fluid flow with no pressure. Open-loop systems use a directional control valve. Less heat is produced in an open-loop system.

Closed hydraulic system: In the closed hydraulic system, the pump operates the fluid with pressure and flows continuously between the pump and the actuator without entering the reservoir The precise response of actuation is the advantage of the closed-loop hydraulic system.

Advantages of Hydraulic System

There are many advantages of a hydraulic system;

- Easy to manage: It is easy to manage and gives accurate results also it is easy to accelerate, start and stop using push buttons.

- Easy maintenance: This system is easy to maintain as it has fewer moving parts. It is also very easy to operate the functions.

- Better lubrication: It has automatic lubrication and also protects the system from any internal damage.

- Safe and secure system: The systems are safe to use in chemical plants and mines as it does not cause sparks.

- Fast transmission of power: Hydraulic system has the ability to transmit power using flexible hoses and tubes as it really works fast in this system.

Disadvantages of Hydraulic System

The disadvantages of hydraulic systems are;

- Environmental problems: In this system, it causes leakage of fluids which is highly dangerous for the environment and its safety. Leaks should be spotted timely and taken great care of problems that are affecting nature and the environment.

- Regular filtration is required: In hydraulic system contaminants damage the fluid contained in the system and hence affect the productivity of the machine for that reason regular filtration is highly recommended.

- Overheat issue: Sometimes the system gets overheated due to oil loss viscosity and that too damages the system and abrupt the productivity.

- Expensive: The system is very expensive as it is operated by air.

- Aeration: The system causes irritating and loud banging noises which result in the entering of air in hydraulic fluids and it can also damage the internal parts of the system.

Comparison Table for Advantages and Disadvantages of Hydraulic System

Advantages and Disadvantages of Hydraulic System are as follows:

| Advantages of Hydraulic System | Disadvantages of Hydraulic System |

| Hydraulic systems are easy to carry out maintenance and also very easy to control and operates. | Wrong hydraulic fluid can cause damage in many ways, hence it is important to use proper fluids. |

| In this system, leakages can be easily spotted. | Constant filtration is required as the unwanted substances spoil the productivity and processing of the system as well as damage air pockets. |

| Hydraulic power or energy can be easily transmitted from one point to another. | Though leaks can be spotted easily but if it is not taken care of then they can restrict the function of fluids, hence one must repair the leaks. |

| It is easy to repair mechanical parts like valves, pumps, gear, motors and hydraulic rams. | Reciprocating compressors are way more expensive and they are not worth spending extra bucks for less efficiency. |

FAQ’s on Advantages And Disadvantages Of Hydraulic System

Question 1.

What is fluid in terms of science?

Answer:

A substance that can flow easily and which has no proper shape and size and in the context of science, it is a liquid substance which transmits power.

Question 2.

What are the types of Hydraulic systems?

Answer:

Reservoirs, Pumps, Valves, and Actuators are the types of Hydraulic systems.

Question 3.

What types of valves are included in Hydraulic Pumps?

Answer:

There are two types of valves included in hydraulic pumps they are Pressure relief valves and Directional control valves.

Question 4.

Does a Hydraulic pump create pressure?

Answer:

As this question relates to much speculation and debate but it is said that a pump produces a flow of fluid which leads pressure to flow the fluid in any form of resistance.

Question 5.

What kind of fluid is used in a hydraulic system?

Answer:

There are three common types of fluid used in the hydraulic systems they are: Mineral-based, Water-based and Synthetics. Mineral-based fluids are mostly used and these fluids are usually low-cost, high quality and easily available in the market.